Table of Contents

A few significant changes are anticipated in introducing new products and bringing inventive new items to market by 2025, particularly in the manufacturing, life sciences, and medical device industries. Product lifecycle management software will be driven by changing market demands and technical improvements. Product Lifecycle Management (PLM) revenue generated USD 6.6 billion in 2023 and is expected to reach USD 25.7 billion by 2034. The adoption of PLM by SMEs is expected to drive this growth, with a compound annual growth rate (CAGR) of 19%, higher than the industry average of 13%.

The technology industry’s software product lifecycle management market is dynamic and quickly developing. It provides solutions to manage a product’s complete lifecycle, from conception to disposal. Businesses may increase cooperation, expedite product launches, and streamline operations with product lifecycle management software. Innovations in digital technologies, rising demand for integrated solutions, and businesses’ desire to remain competitive in a market that is changing quickly are the main drivers of this industry.

Transform Your Software Vision into Reality – Book a 30-Minute Free Consultation!

Mobile App Development Logistics & Supply Chain Development AI and Deep Learning

What is Product Lifecycle Management Software?

Product lifecycle management software is a tool for managing all the data and procedures involved in a product or service lifecycle via international supply chains. Data from things, parts, products, papers, specifications, engineering change orders, and quality workflows are all included in this.

Businesses are changing their operational methods, and supply networks are becoming more global. For instance, a lot of businesses are selling new goods and services using embedded software services like product-as-a-service (PaaS). These companies are learning, as a result, that they want cloud-based agile product lifecycle management software that can assist them in being flexible and responsive.

The enterprise product record and digital foundation that modern PLM software offers for a comprehensive approach to supply chain management and product creation are rapidly making it the cornerstone of business transformation. You may unify your product value chain with integrated business planning and supply chain execution to help drive faster innovations and enhance how products are designed, manufactured, maintained, and serviced when your business processes are linked with today’s product lifecycle management software on a single platform.

Why Is PLM Required for Businesses?

A variety of problems that go outside the purview of design and production arise for businesses that create items. Product lifecycle management software helps teams throughout the company swiftly obtain product information by reducing these problems and assisting in the alignment and integration of essential resources.

PLM was first created by product engineering services companies in the USA to facilitate engineering teamwork on the newest product designs and information management throughout a product’s lifecycle. However, because of their on-premise IT stack, PLM solutions cater to internal staff. As a methodology, product lifecycle management has expanded to cover more areas of the business today, such as sales, marketing, customer service, suppliers, and partner channels.

Original PLM systems were developed by custom software development companies in the USA with the engineer in mind due to the heavy emphasis on engineering. The purpose of legacy PLM was to assist engineers in lowering product costs, speeding time to market, and increasing productivity. The new benefits of product lifecycle management that are available to today’s next-generation product lifecycle management software span the entire company and enable better product quality, even for complex products, faster product launch times, and increased customer transparency and responsiveness.

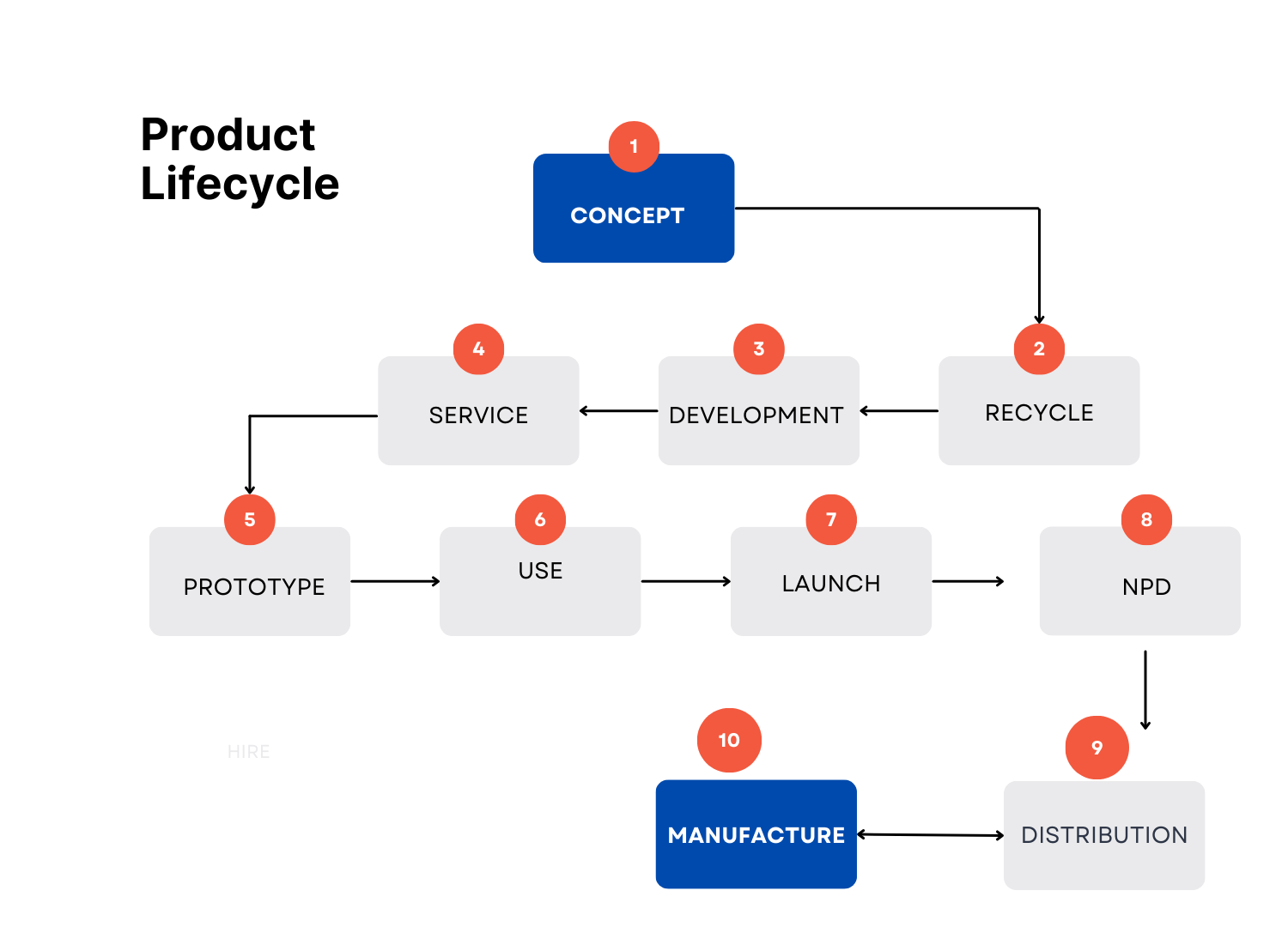

The PLM Process and the Product Life Cycle

The lifecycle of a product usually starts with a concept. It may occur in your car on the way home, at work, or—famously—in a garage in Silicon Valley.

When we consider goods, we typically presume that a concept becomes a design after it gains traction and is then produced for public consumption. The intermediate phases, such as acquisition, maintenance, repair, and finally retirement or disposal, must also be remembered.

A product life cycle consists of four stages, to put it high level:

- Introduction: Expensive and hazardous, newly released items may result in lower sales and more expenses for marketing, R&D, and user feedback.

- Growth: As the product becomes more well-known, sales and earnings increase. To maximize the value, marketing grows.

- Maturity: Marketing strategies that are more targeted and future projections for product enhancements or manufacturing process modifications are determined by the popularity of the product.

- Decline: A product’s popularity will inevitably drop due to rising competition or a decrease in client loyalty. Businesses concentrate on bringing their products to less crowded markets and cutting production costs.

A product’s journey through these four phases and all of the more intricate procedures, including conception, engineering, design, manufacturing, sales and marketing, distribution, servicing, and disposal, is known as its “lifecycle.” Product lifecycle management software is lifecycle management; it aligns people, data, processes, and business systems to ensure the success of the company’s whole product line. The following are essential components of the PLM process.

How is Product Lifecycle Management Changing Manufacturing Industries?

Product lifecycle management software offers businesses several advantages. Time-to-market is shortened, product quality is raised, prototyping expenses are decreased, prospective sales opportunities and revenue contributions are recognized, operational serviceability is maintained and sustained, and the product is guaranteed to satisfy market and customer demands.

PLM reduces waste, improves productivity, and enhances teamwork and creativity. It ensures that the various stakeholders of a given project have the same information at any given time. This eliminates uncertainty and errors by providing a single version of truth. It helps in cutting down on the cost and complexity of time-to-market of new products by providing a structured process for product development.

Shorter Time to Market

One of product lifecycle management software‘s main advantages is its ability to cut time-to-market dramatically. PLM helps to expedite the process of developing new products by offering an organized method for doing so. This shortens the time required to launch a new product. As a result, businesses may have a considerable competitive advantage since they can react to market developments faster.

Moreover, PLM aids in removing ambiguity and mistakes that could impede the creation of new products by offering a single source of truth. By guaranteeing that all parties involved have access to the same information at all times, it lowers the possibility of mistakes and rework, which can impede the pace of product development.

Enhanced Quality of Product

PLM also has the important advantage of greatly enhancing product quality. Product lifecycle management software ensures that quality is ingrained in the product from the outset by offering an organized method for product development. It ensures that the product is serviceable, reliable, and can meet market and customer needs.

Moreover, PLM helps filter out errors that may affect the quality of the product with a single version of the truth. This software re-engineering service decreases the chances of making errors and rework, which may mean lower quality in the output because all parties will possess the same information at any given time.

Lower Prototyping Expenses

Additionally, PLM can lower the cost of prototyping. It helps in the creation of the right product the very first time by providing a structured approach to product development. This phase reduces the need for multiple prototypes, whose manufacture can be costly and time-consuming.

Moreover, product lifecycle management software reduces errors that may require the use of several prototypes by providing a single version of the truth. This serves to reduce the possible risk of errors and consequent rework—possibly involving the use of multiple prototypes—by providing all parties with access to the same information throughout the process.

Enhanced Prospects for Sales and Income Generation

PLM can assist in locating possible sales prospects and raising revenue contributions. PLM helps to guarantee that the product fulfills the needs of the market and the client by offering an organized approach to product development. Sales opportunities and revenue contributions may rise as a result.

Furthermore, product lifecycle management software contributes to ensuring that all stakeholders always have access to the same information. This is possible by having a single source of data. By ensuring that the sales and marketing teams get the data they require to successfully sell and market the product, product engineering services companies in the USA can aid in the improvement of sales and marketing initiatives.

Sustaining and Upholding Operational Dependability

PLM helps sustain and maintain operational serviceability. Product Lifecycle Management (PLM) facilitates the creation of products by offering an organized method that guarantees the product’s serviceability. Both client happiness and service expenses decrease as a result.

Furthermore, product engineering services contribute to ensuring that all stakeholders always have access to the same information by offering a single source of truth. Ensuring that the service crew knows necessary to properly service the product, can aid in improving service efforts.

The Importance of PLM-Powered Digital Twins

A digital twin is a digital copy of a real asset. Digital twins use a product’s historical, representational, and current data combined to depict how it is used in the real world. Making data available for a physical object allows us to create a digital twin, or virtual profile, of that object by simulating its behavior through computer simulation. Custom software development consulting allows for the modeling of the object’s behavior during various stages of its lifecycle, from design and construction to maintenance and manipulation.

Networked systems with a shared digital thread unlock peak digital twin effectiveness. This can be achieved with PLM 4.0, a contemporary product lifecycle management software. Real-time updates to the digital twin ensure everyone has access to the latest data for informed decisions. Digital twins evolve. They change with time.

Rich data from across the lifecycle feeds the digital twin, empowering custom software development to optimize product design, performance, and cost through simulations and what-if scenarios. The data is examined in real-time as it comes in. Do you want to alter a product without first creating a prototype? Simulate your virtual twin. Do you want to know if a factory machine’s ball-bearing replacement will cut down on production downtime?

PLM and Digital Thread

Technology breakthroughs that enable custom software development solutions USA to react swiftly to change make new business models, business transformation, and Industry 4.0 feasible. Software product lifecycle management of today serves as the cornerstone and point of junction for crucial, lifecycle-spanning product processes, intertwined with real-time data from technologies like machine learning (ML), artificial intelligence (AI), and the Internet of Things (IoT). Global corporations are transforming the way they develop, manufacture, and support products by utilizing what has become known as a “digital thread.”

A collaborative, one-data platform that is exclusively possible with next-generation PLM software is what is known as the “digital thread.” This platform creates a comprehensive view of a product’s physical and digital data throughout its lifecycle by connecting all aspects of the organization and its data. The digital thread facilitates a smooth flow of controlled data between corporate systems, processes, partners, and ecosystems. It starts at the very beginning of ideation and design and continues through manufacturing, supply chain, and service.

The digital thread dismantles barriers between hitherto disjointed and compartmentalized systems and speeds up commercial value. At every stage of the product value chain, including early product design, operations, production, service, and end of life, it lessens the latency and complexity of having to gather information across supply networks and communicate it. In conjunction with real-time transactional data, the digital thread provides the necessary insights to enable prompt, better-informed, and proactive decision-making. The digital thread that today’s product lifecycle management software offers allows you to access the appropriate information at the appropriate time and location, enabling you to break down organizational barriers and unlock speed and agility while maintaining the greatest level of product quality.

Key Components of PLM

Product and Portfolio Management, Product Design, Product Development, and Product Data Management are the four main components of PLM.

Product and Portfolio Management

A company’s product portfolio can be optimized through the strategic process of portfolio and product data management software, which aims to match product investments with strategic goals and strike a balance between risk and reward. It entails conducting market research, seeing possibilities, selecting which goods to invest in, and maintaining the portfolio of products during the product’s lifetime.

PPM guarantees that a business is investing in the proper goods. This is essential to the success of a product lifecycle management software strategy. It assists in making sure that the company invests in products that will yield the highest return on investment. That its product portfolio is in line with its strategic objectives.

Product Design

Product design is a process for developing a new product that a company will sell. The steps in the process are to design a product, build the prototype, and then test it. Making a product that satisfies market and customer demands is PD’s main objective.

Because PD is where the product is developed and created, it is an essential part of product lifecycle management software. This stage decides the form, fit, and function of the product, along with its specifications.

This stage also identifies and resolves potential production problems, while considering the product’s manufacturability.

Product Development

Product development refers to the process of introducing products into the market. The process consists of the generation of a product, testing of the product, and manufacturing process preparation for the product. What PD would like to do is develop a product that’s both reliable and manufacturable but meets the needs of the market and the customer.

Since PD is where the product is designed and made ready for manufacturing, it is an essential part of product lifecycle management software. This stage specifies the manufacturing procedure for the product and finalizes its design. Additionally, after testing, it addresses any potential quality problems.

Product Data Management

The practice of managing and exchanging product data inside an organization and during a product’s lifespan is known as product data management software or PDM. The procedure entails gathering, arranging, and maintaining the product-related data. Ensuring that the data is correct, current, and available to all stakeholders is the aim of PDM.

Because product information management software is where the product’s data is managed, it is an essential part of PLM. It is the location for managing and storing the design, production, quality, and specification data for the product. To guarantee that everyone knows necessary to perform their tasks well, it is also the location where the data is made available to all stakeholders.

Unlock Your Business Potential with Custom Software Solutions. Contact us Today!

Common PLM Software Challenges

PLM platforms are an excellent way for custom software development outsourcing to avoid problems with manufacturing and product development. Nonetheless, there are a few typical problems that arise. Here are some ideas to assist address these issues, which range from poor change management to dealing with data silos.

Inadequate procedures for managing change

An inefficient change management procedure is a frequent product lifecycle management software problem that can arise from unclear or poorly established approval routing procedures. Organizations run the risk of introducing miscommunications into production if there are no clear guidelines for the approval, recording, and implementation of modifications, as well as no precise instructions about who must be involved. This can also significantly extend the time needed to get development clearance and acquire changes.

Unable to obtain the knowledge needed to make decisions

Product lifecycle management software handles intricate data administration. Certain PLM systems have restricted data access for team members, departments, or outside stakeholders, which increases the complexity. Access control rules, a confusing interface, or a lack of integration support could be the causes. Because of this, certain team members might not be aware of the most recent design release or whether the data in the PLM corresponds with that in the CAD or ERP systems. A central platform that is simple to link with other business tools can help teams in an organization become more coordinated and improve decision-making.

Diverse information between your software platforms

Information that is separated between teams, departments, or branches within an organization is referred to as a data silo. Typically, the best custom software development company has a wide variety of data sources spread across several systems. This comprises data on resources and workflows in ERP systems, designs from CAD, needs from requirements management systems, and content collected from multiple distinct parts suppliers. This seclusion results in information that some teams are unable to access.

Prolonged intervals between receiving approval or feedback

Miscommunications may result in mistakes that are not noticed. It’s difficult to identify which data is the most recent when there are data silos. After a product is put into production, it may also present problems for the custom enterprise software development that develops it. Production insights get stuck, hindering continuous improvement between engineering and design. Errors in part data, redundant information, and problems with a design’s manufacture are possible additional problems.

Implementation taking too long

Although product lifecycle management software offers numerous advantages, a protracted deployment period can significantly reduce the value and hinder the return on investment of a PLM tool. This is particularly true now as businesses need to operate quickly to remain competitive. The days of taking many months to onboard and install a PLM are long gone.

Future of Product Lifecycle Management

The product lifecycle management software is changing. In a dynamic custom enterprise software development environment like today, it is all the more important to have a modern PLM system in place since it will help you adjust to changing circumstances, which include:

More life cycles of products.

- Dependence on foreign suppliers

- ability to adapt to changes in the market and

- shortage of individual components increasing demand for automation and data transparency.

Growing competition, and shortening time-to-market

A changing, dispersed workforce that relies on software platforms and cloud-based communications for sharing information

Custom enterprise software development requires the capability to utilize PLM software in the fast acquisition of the latest supplier data, finding modifications, designing a change, reusing components, and evolving the product. PLM solutions are thus developing to become more agile and to pace up decision-making at a faster rate. Some of the trends transforming the environment of product lifecycle management software are as follows:

The ecosystem of connected suppliers

It takes a great many things to help get products to market faster. The result is that an ecosystem of cloud-native custom software development services connecting data sources is starting to emerge.

Product lifecycle management software integrates with enterprise resource planning, requirement management systems, and computer-aided design technologies to centralize and manage product data.

Greater supplier data openness will simplify future data portability. This will enable all the relevant parties to have access to the information they require and to communicate with design engineers with more ease from outside manufacturers and suppliers.

The impact of items on the environment can be monitored when

- The businesses will look for ways to trace the carbon footprint and other ecological effects of their products in an increasingly ecologically aware market.

- Product lifecycle management software will provide tools to calculate and understand a product’s carbon footprint related to design decisions. As companies face increasing liability for sourcing and disclosing their impact, this approach will become even more important moving forward.

AI-assisted design

Artificial intelligence is finding its way into many areas. Some amount of automation is already a part of PLM platforms. Soon they will develop machine learning capabilities and learn from data to send out alerts and recommendations to users. This will help in making better decisions concerning profitability It can be as simple as automatically providing the user with recommendations for the ideal component from a massive number of vendors or even letting them know if a design they already have could be easily adapted for what they need.

Smart analytics functionality in product lifecycle management software will help managers:

Visualize the implications of changes altogether

- See complete product genealogy to identify trends.

- Use data from every stage of the product life cycle to come up with new products and anticipate market trends.

Conclusion

Trends like cloud-based solutions, IoT connectivity, application re-engineering services, and a focus on sustainability are fueling great growth and innovation in product lifecycle management. The adoption of digital twin technology, AI, and machine learning is going to change product development and lifecycle management processes forever. It assists in productivity improvement and accelerates time to market. While industry-specific product lifecycle management software are meeting most of the requirements for many sectors, collaborative and cross-functional PLM platforms are inspiring collaboration, and ingenuity within businesses. The PLM market will still be at the forefront of technological progress as long as companies have adopted digital transformation and an increase in the need for sustainability and efficiency. With these trends embedded into the product lifecycle management software strategy, businesses will gain a competitive edge and drive innovation in their respective sectors.