Heimler’s Journey From Blind Spots to Business Clarity – A3logics Unleashes the Power of Live Intelligence

Discover More

Redefining the Future of Lending – Cred Fintech’s Monumental Transformation with A3logics

Discover More

Revolutionizing Credit Risk – How A3logics and Heimler Redefined Trust and Precision with Machine Learning

Discover More

Transforming Risk to Opportunity – A3logics and Heimler Revolutionize Credit Risk Modelling

Discover More

Harness our expertise in Industrial IoT Solutions. Optimize your processes, enhance quality, and drive accelerated business growth with our tailored IoT innovations. Our predictive maintenance capabilities allow you to foresee and address potential downtimes before they occur, minimizing disruptions and maximizing productivity.

Our team of IIoT experts helps define roadmaps, assess maturity, identify focus areas, facilitate technology evaluations, and pilot concept feasibility through proofs-of-concept. This ensures initiatives achieve their intended goals.

We design and develop end-to-end customized solutions right from connectable devices, and edge gateways to data platforms. Our solutions seamlessly integrate legacy & new systems for maximizing ROI of clients’ existing investments.

As an Industrial IoT development company, we specialize in integrating greenfield and brownfield systems– connecting devices, historians, cloud platforms, analytics models, and third-party APIs for interoperable solutions.

We help set up scalable on-premise infrastructure as well as migrate solutions to private or public clouds through microservices-based architectures. This ensures flexibility, security, and cost optimization.

We work with experts who can program the firmware, and operating systems and develop apps for deploying IoT devices with required functionalities. Also, we have the expertise to future-proof devices through regular firmware updates.

We implement data lakes, and configure data pipelines and integration tools. Combined with machine learning models, this helps derive real-time insights from industrial datasets for predictive and prescriptive actions.

IIoT has widespread applications across manufacturing, energy, transportation, and more. At A3Logics, we leverage our extensive domain expertise and technology skills to develop specialized IIoT solutions for key industries.

We deploy sensor-based systems that can precisely detect anomalies in machines, predict failures, and schedule maintenance. This eliminates unexpected shutdowns and improves overall equipment productivity and lifespan.

Our RTLS and sensors-based solutions provide real-time visibility of valuable assets like vehicles, containers, and tools within premises on an interactive map. Improved traceability boosts operational efficiency.

Our end-to-end supply chain solutions equipped with IoT devices offer global visibility of materials and goods in transit. Dynamic ETA alerts and quality checks ensure just-in-time deliveries and quality compliance.

Through PLCs, DCS, and SCADA integrations we develop interactive plant floor systems for automated material movement, mixing, packaging, waste handling, etc. Headless operations increase volumes and consistency.

Our RFID/barcode-based solutions equipped with edge controllers accurately track stock levels in real-time, auto-generate replenishment orders, predict out-of-stock, and enable targeted replenishment.

Our non-invasive sorting machines, vision systems, and lab automation applications powered by ML/AI help manufacturers consistently achieve stringent quality standards and certifications.

With industry experience, our customized IIoT solutions help discrete and process makers achieve Industry 4.0 goals of smart, connected factories through technologies like Machine Learning, distributed ledgers, and advanced visualization dashboards.

Our experts help maximize asset productivity through remote monitoring of field equipment and pipelines. IIoT helps predict failures, analyze anomalies to optimize performance, and avoid unplanned downtime, which is critical for 24/7 operations.

Environmental safety and regulatory adherence are vital. We optimize complex batch processes leveraging real-time data from connected instruments and distributed control systems for maximizing yields and reducing changeover times.

We partner with tier-1 component makers and OEMs to develop solutions like predictive quality solutions, and automated guided vehicles for factories of the future with plug-and-play integration of robots, and AGVs into existing infrastructure.

End-to-end digital traceability, quality control, and regulatory compliance are key challenges we help overcome through smart solutions that leverage technologies like computer vision, real-time process monitoring, and analytics dashboards.

Through strategic implementation, we ensure that your business achieves significant performance improvements, cost savings, and operational efficiency.

We offer comprehensive in-house capabilities for end-to-end solution delivery, ensuring seamless execution without reliance on external partners or dependencies.

By collaborating with leading technology providers, we ensure access to the most advanced tools and platforms, tailored to your specific needs.

We ensure full compliance with industry regulations and global standards like GDPR, HIPAA, and ISO, helping your business meet legal requirements and avoid penalties.

We provide dedicated global delivery centers combined with skilled local talent to ensure responsive and personalized customer support. Our global reach allows us to serve clients across different time zones, while our local teams deliver culturally aligned and region-specific solutions/p>

A3logics redesigned the logistics software of a mobile app solutions company’s end customer. The project included creating a comprehensive solution with reporting features, order tracking, and system updating.

“Their distinct flexibility and their strong communication were the project’s main assets.”

A construction technology company hired A3logics for custom software development. They created a construction digital platform that allows users to see project areas, distribute resources, and share data.

“Their software has proven essential in the construction sector.”

A3logics created and implemented a custom logistics software solution for a wealth management platform. This included developing features and integrating real-time tracking and data analytics functionalities.

“They ensured our collaboration went well by providing timely items and responding quickly to our requests.”

A3logics created and executed a personalized Generative AI system that featured chatbots for customer service, prediction algorithms, and AI-powered data analysis tools.

“Their technical expertise and reactivity were excellent.”

A3logics has developed an administrative management system for a health testing company. The product is designed to handle operations such as consultant matching, time reporting, and compensation management.

“The collaborative team we’ve worked with has shown great flexibility and excellent project integration.”

A transportation company hired A3logics to create a custom software program for freight activity tracking. The team also created invoicing tools and a driver-tracking system connected to a dispatch system.

“Their thorough inquiry and engagement with our team reflect their commitment to understanding our requirements.”

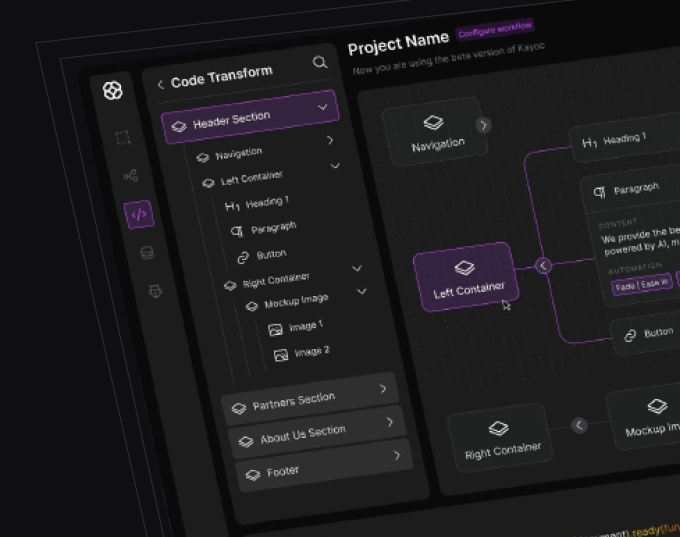

Successful IIoT projects require expertise across IoT, cloud, edge computing, data engineering, AI/ML, cybersecurity, and experience integrating legacy and new systems. Consulting, customized solution delivery, and integration capabilities are vital to realizing ROI from IIoT deployments.

Marketing Head & Engagement Manager