Heimler’s Journey From Blind Spots to Business Clarity – A3logics Unleashes the Power of Live Intelligence

Discover More

Redefining the Future of Lending – Cred Fintech’s Monumental Transformation with A3logics

Discover More

Revolutionizing Credit Risk – How A3logics and Heimler Redefined Trust and Precision with Machine Learning

Discover More

Transforming Risk to Opportunity – A3logics and Heimler Revolutionize Credit Risk Modelling

Discover More

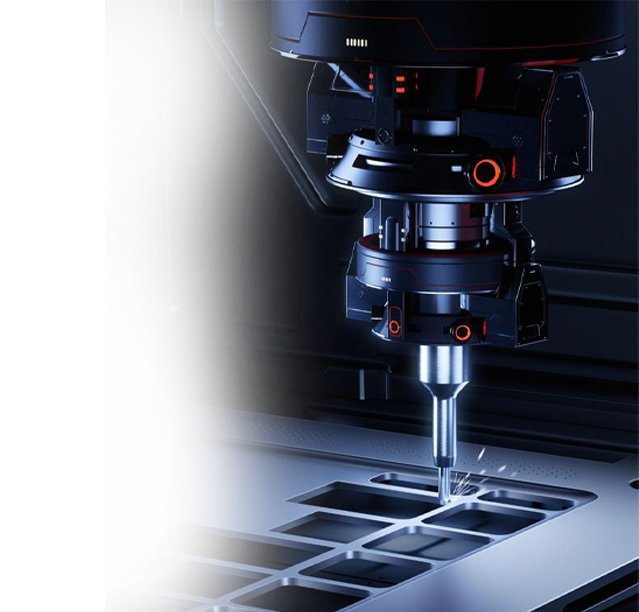

At A3Logics, our manufacturing software services provide exponential business value. Our manufacturing software development services are specifically engineered to address manufacturers’ unique challenges, including inventory control, supply chain management, production planning, and quality control.

A3Logics offers cutting-edge cloud-based MES services that optimize manufacturing operations and improve productivity. These services provide real-time insights and seamless integration with existing systems.

Our IoT services empower manufacturers to transition to Industry 4.0 with connected devices and intelligent systems that boost efficiency and innovation.

A3Logics’ predictive maintenance services use AI and machine learning to anticipate equipment failures, minimize downtime, and optimize maintenance schedules.

Our RPA services automate repetitive tasks in manufacturing and back-office processes, enhancing efficiency and accuracy across operations.

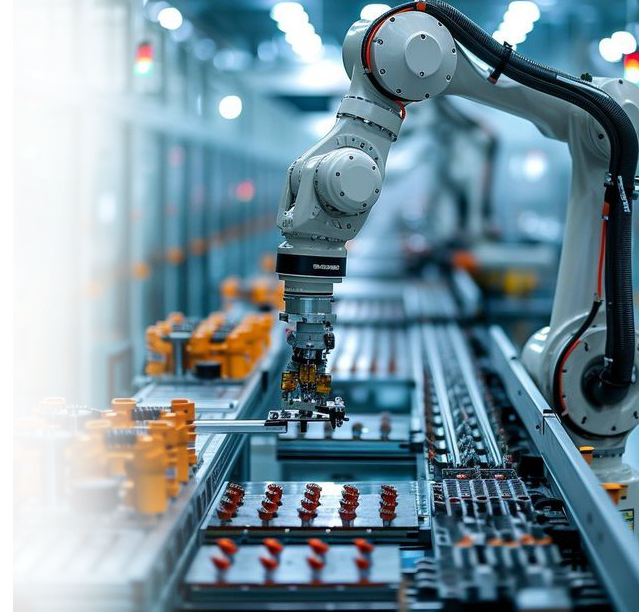

A3Logics specializes in designing collaborative robots (cobots) powered by AI, improving worker productivity and safety in manufacturing environments.

Our AI services for assembly lines enhance production efficiency and reduce operational costs by leveraging advanced analytics and automation.

We implement the latest AR/VR technology in our manufacturing software development services, enabling better visualization and smoother handling of the process for improved customer experience.

We provide AI-driven manufacturing development services that position manufacturers at the forefront of Industry 4.0 by enhancing operational efficiency, improving product quality, and aligning production with customer demands.

Implement customized blockchain services to enhance your systems processes’ security, transparency, and traceability. This approach streamlines supply chain management, monitors product provenance, and ensures data integrity. It also implements state-of-the-art decentralized technology.

We develop AI software solutions that are both efficient and effective in optimizing inventory control and order processing. Our solutions enable you to achieve efficient operations and satisfied customers by streamlining order fulfillment, monitoring inventory levels in real-time, and minimizing stockouts.

We create predictive maintenance solutions that reduce downtime and prevent expensive equipment malfunctions. Our systems utilize machine learning algorithms to anticipate potential issues, facilitating proactive maintenance scheduling to avoid operational disruptions.

To optimize the development of products, we create Product Lifecycle Management (PLM) systems. Manufacturers can expedite the time-to-market and improve the quality of their products by utilizing custom PLM systems, which manage product data, automate workflows, facilitate collaboration, and optimize product life cycles from concept to retirement.

We develop condition-monitoring software that employs AI algorithms to prevent equipment malfunctions and reduce downtime. Our software ensures uninterrupted production by continuously monitoring equipment health, detecting anomalies, and triggering alerts for proactive maintenance.

Quality control and compliance processes, including audits, non-conformance management, and corrective procedures; with our solutions, these processes are simplified to ensure product quality and regulatory compliance.

Build stronger client relationships and boost revenue with our unique CRM software. Our system helps you manage lead data, track sales pipelines, increase team communication and collaboration, and provide excellent customer service by getting insights into customer wants and market trends.

Reform your manufacturing practices by implementing the latest IoT technology into your process. We develop custom IoT solutions tailored to your business needs to streamline your workflow and management.

IoT-powered services track equipment, raw materials, and finished goods. These systems improve visibility, prevent loss, and optimize asset utilization, ensuring smooth operations across manufacturing facilities.

Develop tailored IIoT platforms integrating devices, sensors, and machinery into a unified system. These platforms enable real-time data collection, monitoring, and analytics, driving smarter decision-making and enhanced productivity.

Enhance manufacturing efficiency with IoT-enabled robotics and automation systems. These services enable precise control, remote monitoring, and predictive maintenance of robotic systems, ensuring uninterrupted production workflows.

Leverage IoT to collect and analyze production line data in real time. This ensures process optimization, identifies bottlenecks, and enables predictive maintenance to minimize downtime and improve overall productivity.

Deploy advanced IoT security systems to safeguard devices, networks, and data from cyber threats. Detect vulnerabilities and implement robust access control measures to ensure the integrity of manufacturing operations.

At A3Logics, our Data Analytics and Business Intelligence Services are designed to revolutionize manufacturing operations by transforming raw data into actionable insights.

Utilize advanced analytics to monitor production quality in real-time. These BI tools detect defects, track process variations, and ensure compliance with quality standards, reducing waste and improving product reliability.

Discover More

Leverage Business Intelligence predictive analytics to forecast market demand and optimize inventory levels. This helps manufacturers avoid overstocking, minimize stockouts, and effectively align production with customer needs.

Discover More

Integrate with analytics platforms to gain insights into equipment performance, operational efficiency, and production trends. This leads to better decision-making and maximized factory output.

Discover More

Analyze operational and production costs to identify inefficiencies and potential savings. Data-driven insights enable manufacturers to streamline processes, reduce waste, and optimize resource allocation.

Discover More

Deploy data analytics to identify vulnerabilities and mitigate risks in manufacturing systems. Monitor network activity and use predictive models to prevent data breaches and ensure the security of sensitive information.

Discover More

Optimize energy usage with analytics that monitor and evaluate consumption patterns across facilities. These tools help reduce energy costs, improve sustainability, and achieve regulatory compliance in energy management.

Discover MoreA3Logics utilizes advanced technologies such as AI, blockchain, and IoT to deliver next-gen Manufacturing software solutions. We empower insurers with tools for automated claims processing, risk analysis, and seamless policy administration to stay ahead in a competitive market.

We focus on designing intuitive, user-friendly interfaces to enhance agent and customer experiences. Our custom solutions simplify complex Manufacturing processes, driving engagement and operational efficiency for insurers and their clients.

Our Manufacturing software services have industry-leading security features, ensuring data protection and adherence to regulatory standards such as HIPAA, GDPR, and PCI DSS. This reduces the risk of breaches and maintains compliance.

We ensure effortless integration with existing systems, such as CRM, ERP, underwriting platforms, and third-party APIs, creating a unified platform for efficient operations, data management, and enhanced decision-making.

Experience the capabilities of our Manufacturing software development services with our flexible try-and-buy model. Test-drive our services risk-free to evaluate their performance, scalability, and alignment with your business goals before committing fully.

A3Logics provides comprehensive support and maintenance services to ensure your Manufacturing software remains reliable, up-to-date, and optimized. From regular updates to quick issue resolution, we keep your systems performing at their best.

A3logics redesigned the logistics software of a mobile app solutions company’s end customer. The project included creating a comprehensive solution with reporting features, order tracking, and system updating.

“Their distinct flexibility and their strong communication were the project’s main assets.”

A construction technology company hired A3logics for custom software development. They created a construction digital platform that allows users to see project areas, distribute resources, and share data.

“Their software has proven essential in the construction sector.”

A3logics created and implemented a custom logistics software solution for a wealth management platform. This included developing features and integrating real-time tracking and data analytics functionalities.

“They ensured our collaboration went well by providing timely items and responding quickly to our requests.”

A3logics created and executed a personalized Generative AI system that featured chatbots for customer service, prediction algorithms, and AI-powered data analysis tools.

“Their technical expertise and reactivity were excellent.”

A3logics has developed an administrative management system for a health testing company. The product is designed to handle operations such as consultant matching, time reporting, and compensation management.

“The collaborative team we’ve worked with has shown great flexibility and excellent project integration.”

A transportation company hired A3logics to create a custom software program for freight activity tracking. The team also created invoicing tools and a driver-tracking system connected to a dispatch system.

“Their thorough inquiry and engagement with our team reflect their commitment to understanding our requirements.”

By increasing stakeholder engagement and communication, streamlining inventory management, and boosting demand forecasting accuracy, we provide tailored manufacturing solutions essential to supply chain optimization.

Marketing Head & Engagement Manager